The Lab

Every Delta Three Oscar product and material is the result of extensive R&D caried out in our state-of-the-art innovation center where we ensure everything matches our commitment to making the world's best protection.

Our capabilities span across three main areas: Science, Engineering and Design.

Delta Three Oscar Lab

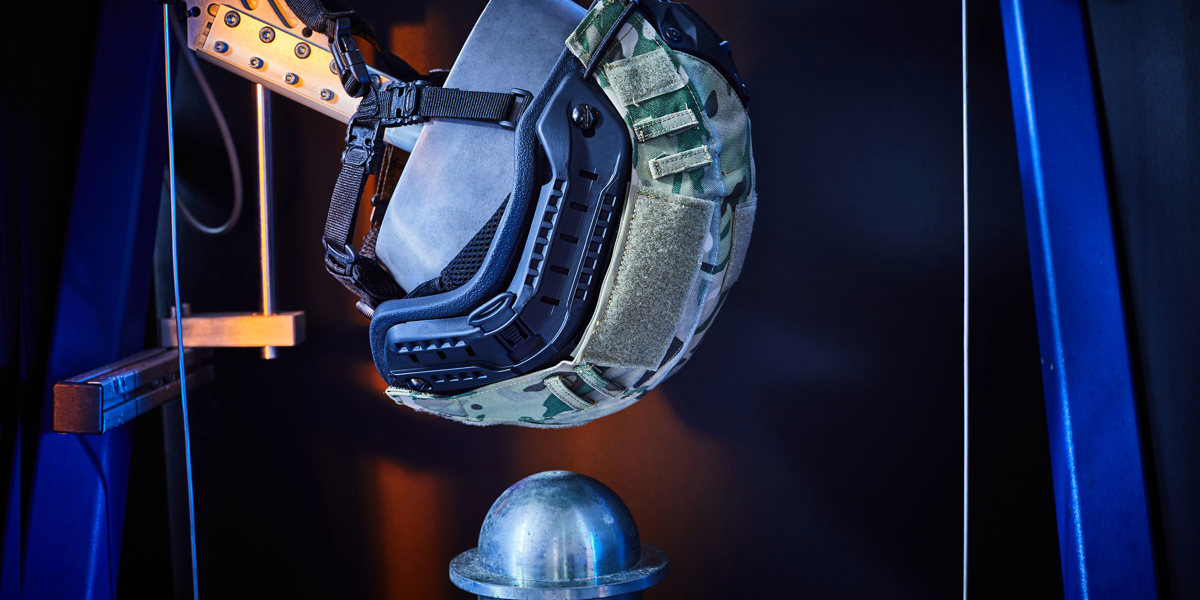

As D3O’s tactical arm, Delta Three Oscar maximizes over two decades of materials science and design dedication proven to protect the world leading athletes, powersports champions and adrenaline chasers. The lab, located at D3O headquarters in London, is where the best protective concepts are born and developed through application of state-of-the art methods of chemistry and manufacturing all for the benefit of the warriors we protect from debilitating long-term consequences. We protect those who protect us, as the industry authority on impact protection.

Our team and facilities are dedicated to the research, development and testing of materials and products that are geared to withstand the intense forces of real-life impact scenarios. And we don’t stop there - we combine the best minds from independent test labs, non-profits, and academia and apply the most advanced concepts in order to stay at the forefront of kinetic impact energy reduction technology. Through doing this we have established industry benchmarks such as the simultaneous 10- and 14-foot per second impact performance requirement now specified by the US Department of Defense for forward deployed operators outside the wire.

Innovation Center

The D3O lab is a state-of-the-art innovation center taking material and product solutions from initial concepts to full-scale production. Prospective products undergo a grueling battery of tests, trials and extensive scrutiny and evaluation. At each stage in the development process, they are assessed for their ability to provide additional benefits such as performance stability, weight reduction and comfort. On-site capabilities include material formulation, tooling, rapid prototyping, and micro-operations for samples.

Science

At the core of D3O's innovation is our dedication to scientific excellence. The scientists in our London Lab push the boundaries of material science by leveraging advanced chemistry and physics to develop unique formulations that offer unparalleled, purpose-fit protection.

Our suite of patented and proprietary materials undergoes rigorous testing to ensure they meet the highest standards of safety and performance, making D3O the trusted choice for protective solutions across multiple applications and sectors.

Engineering

Engineering excellence is the backbone of D3O's product development, where our engineers leverage expertise in tooling, prototyping, and testing to create innovative products. Utilizing advanced manufacturing processes and precision engineering, we ensure every D3O product meets the highest standards of quality and durability.

Our engineers employ the latest tooling techniques, rapidly iterate designs through prototyping, and conduct rigorous testing at every stage to validate product performance. Dedicated to continuous improvement, our team integrates real-world feedback and technological advancements to deliver the best possible protection.

Design

Design is a crucial element in the creation of D3O products. Our design team collaborates closely with our scientists and engineers to transform groundbreaking protective materials into practical, user-friendly solutions.

We focus on creating products that not only offer superior protection but also integrate seamlessly into the lives and activities of our users. From award-winning light and breathable motorcycle protectors to knee-saving workwear inserts, our designs are both functional and aesthetically pleasing, ensuring that our customers never have to compromise on style or safety.

Our Solutions

Our Certifications

Delta Three Oscar News

Read more

Read more

Read more